Fangdee yun MES: seize the opportunity of digital transformation and move towards a smart factory

With the popularization of Industry 4.0 and advanced manufacturing concepts, new technologies such as the Internet, big data, artificial intelligence, and the Internet of Things continue to make major breakthroughs. Global manufacturing industries are constantly exploring new ways to break through development bottlenecks. In this context, China's manufacturing industry is facing unprecedented changes and opportunities. Among them, MES system has become a booster to achieve this goal, which will greatly enhance the competitiveness of enterprises. It can be said that manufacturing enterprises urgently need MES systems.

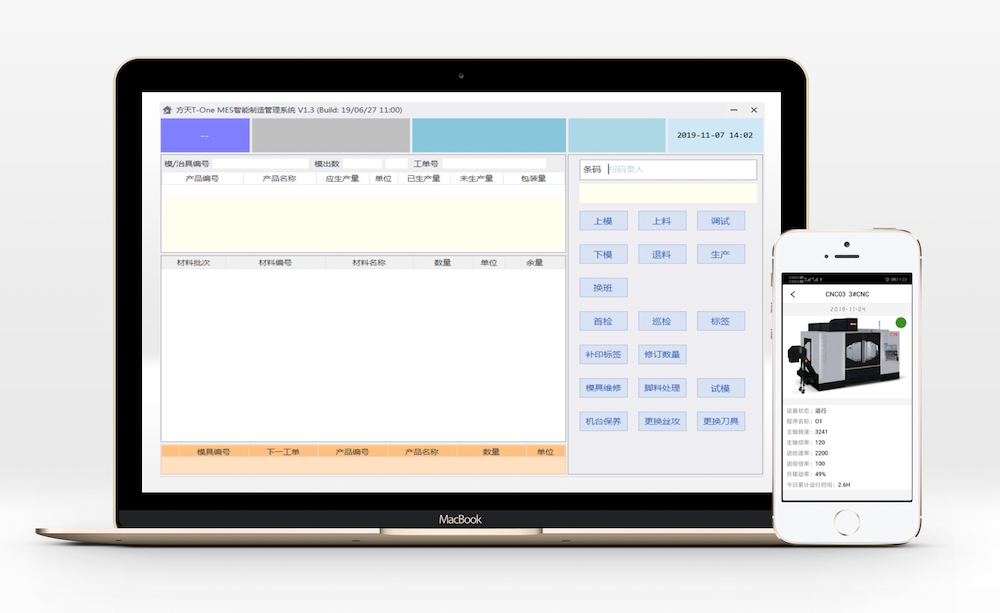

Fangdee yun MES manufacturing execution software system provides order management, production planning, production process control, material inventory management, product quality management, multi-dimensional analysis reports and other refined product life cycle management. Help enterprises integrate the supply chain, realize an integrated workshop management mode, and improve the ability of automated workshop execution; create a lean and visual automated production workshop, improve production transparency and production efficiency, build a digital factory, and realize intelligent manufacturing. Help companies around the world gain lasting competitive advantage by realizing innovations that truly impact future development.

product features

An industrial cloud MES platform based on the Internet of Things and focusing on manufacturing enterprise industry chain services

cloud platform

Cloud computing has significantly reduced the cost of enterprise application software.

Machine networking

Data collection, automatic collection, without manual intervention.

Big Data

Big data science analyzes the factors of enterprise production problems.

Key applications

Build a Digital Smart Factory and Make Enterprise Management System Effective

Schedule

Process control

Quality Management

data collection

Visual management

Equipment maintenance

Schedule

Based on the premise of limited resources and capabilities, the shop scheduling is optimized through corresponding job sequencing and job scheduling, which minimizes the preparation time in the production process and improves the operation efficiency and performance of the production process.

粤公网安备 44190002004391号

粤公网安备 44190002004391号