Business excellence

20 years of technology precipitation and professional coaching team to help companies achieve business excellenceERP system scheme of mold base / mold embryo industry

Characteristics and management problems of mold base / mold embryo industry

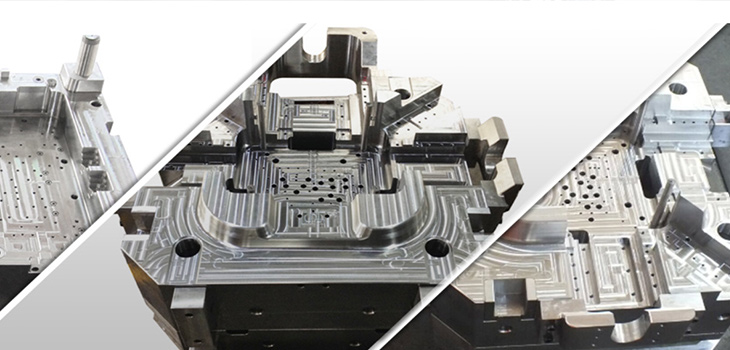

Mold application involves every product (such as automobile, aerospace, daily necessities, electrical communication, medical products and equipment, etc.), as long as there are a large number of products, mold production will be applied, and mold base is an integral part of the mold. In short, the mold base has a pre forming device, a positioning device and a ejection device. Generally, it is equipped with panel, panel a (front template), panel B (rear template), panel C (square iron), base plate, thimble panel, thimble base plate, guide post, return pin and other spare parts. The mold base is composed of several plates and mold base accessories. The production and manufacturing process of a set of mold base is the process of manufacturing the steel through several processing technologies to meet the requirements of the plates, and then assembling the plates. According to the actual situation, it is divided into standard mold base and non-standard mold base.

- The mold base is a semi-finished product of the mold, which is composed of various steel plate matching parts. It can be said that it is the skeleton of the whole mold.

- In addition to purchasing customized mold base, mold manufacturers can also choose standardized mold base products. Mold base style diversification, and delivery time is short, even buy and use.

- Due to the great difference in the processing involved in the mold base, the mold base production is a typical one-piece production, with unique rules in production process and management mode.

- The engineering department designs the mold base production process drawings, and the process drawings, production orders and production reports are distributed to the production department. The production department organizes the production and ensures the timely delivery.

- What is the current surplus production capacity of the enterprise. How to estimate the contract delivery time of mold base.

- How to organize the production of hundreds or even thousands of mold bases at the same time, how to install the internal processing and external processing of the plate factory, etc.

- How to make full use of the existing production resources and capacity reasonably, effectively and fully.

- How to master and control the production progress of mold base in real time.

- How to control and evaluate the machining quality of mold base.

- How to calculate the production cost and personnel performance of mold base accurately and quickly.

- The gross profit and net profit of each order are calculated according to the weight of die plate, the price of steel, the cost of accessories and the processing cost.

ERP system solution for mold base / mold embryo industry

The ERP management software system of Fangdee mold base industry is a professional customized version combining the industry characteristics of mold base / mold base manufacturing enterprises. From the mold base quotation, design, planning, procurement, processing, assembly and other whole process management system, to help customers realize the integrated management of enterprises. The system takes PDM design as the source, PS project as the main line, APS scheduling as the guidance, MES application as the basis, and financial management as the center. At the same time, it organizes and weaves the production of hundreds of mold embryos / mold bases. Solve the problems of mold base production, schedule, performance, quality, drawing and file. So as to ensure the quality of mold base, reduce the cost of mold base factory, shorten the business objectives of mold base manufacturing cycle. Visual Kanban is used for the design progress, procurement progress, processing progress and assembly progress to realize the systematic management and lean production of mold base factory.

- It can calculate material cost, processing cost, logistics cost and so on.

- Material weight and material cost can be calculated according to mold model, specification and size, ABC board thickness, etc.

- The cost of accessories can be calculated according to the model and specification of the mould, such as the TOS, the middle TOS, etc.

- According to different mold base models, you can set the material, accessory properties and consumption corresponding to the model.

- Evaluate the remaining capacity of the current enterprise and quickly reply to customer delivery date.

- Provide a set of project management tools to help managers and customers follow up the production progress of each mold base online.

- Quickly and easily develop the processing route of the plate, and automatically evaluate the planned working hours according to the processing procedure sheet.

- Reasonably and orderly arrange the internal processing, external processing, purchasing, etc. of the panel, and formulate the production plan.

- In the process of production, emergency and order insertion are frequent, so the process planning can be adjusted quickly to solve the scheduling problem.

- Maximize resource efficiency, master equipment load in real time, and avoid a lot of unnecessary overtime or outsourcing.

- Workshop statistics automation, through bar code or machine networking system, the management personnel are free from the tedious daily data statistics and concentrate on product and process improvement.

- Master and control the production progress of mold base in real time, and each workpiece is in a controllable state.

- To control the process inspection and prevent the unqualified products from flowing into the next process.

- Master the cost of mold base manufacturing, daily performance at a glance.

- Standardize the management of mold / mold base enterprise, establish the ERP system of mold base, and establish the operation system of the enterprise at the same time.

粤公网安备 44190002004391号

粤公网安备 44190002004391号